Driven Broaching Unit - OD and face mounted

The new state of the art broaching unit for economic manufacturing of oriented keyways and splines.

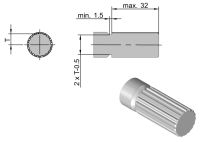

- Working stroke:

- Total stroke:

- Max. groove width:

- Workpiece material:

- Max. stroke:

- Ratio:

- Max. feed per stroke:

- Direction of cut:

- 32 mm

- 35 mm

- 10 mm

- up to 1.000 N/mm²

- 1.000 1/min

- 1:1

- 0,15 mm

- X+ oder X-

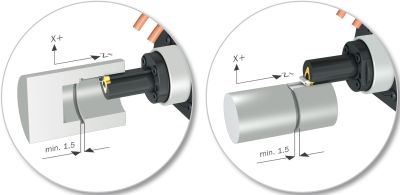

Same insert holder for ID and OD broaching – Simply by rotating insert holder 180 degrees.

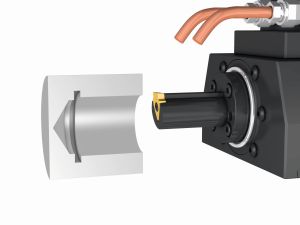

Function

Position insert on Z

Cutter drives into workpiece

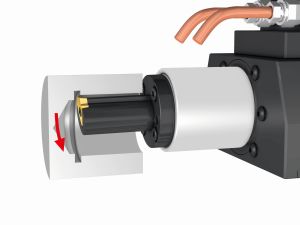

Cutter lifts from workpiece

Lift-off function prevents wear/breakage when cutter retracts

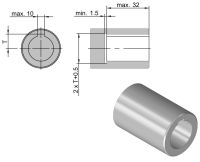

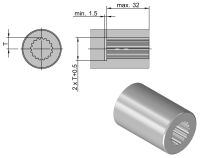

Sample workpieces

- Keyway

- Internal involute spline according to DIN 5482

- External involute spline according to DIN 5480