Description

Key Features

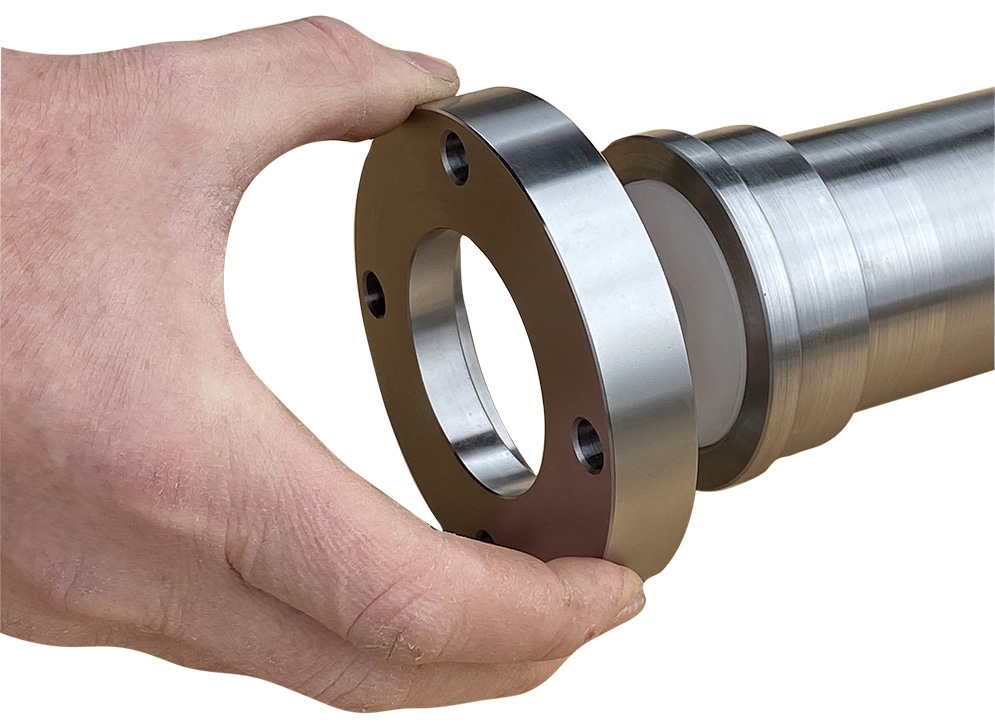

This master liner is manufactured to a high tolerance from steel tubular material.

The bore is made as large as possible and inside the bore of the liner there are a number of spacers and Acetol bushes. The bore of the bushes are machined to suit a material size with a small amount of clearance.

The advantage of this system is that the liner remains housed inside the spindle and the internal bushes are changed for each material size. This system is normally utilised on fixed headstock lathes fitted with a short magazine barfeeder however they can be used with full length magazine barfeed that uses guide channel that is smaller than the lathe spindle.

In general they are used on fixed head lathe but they can be used on sliding head, moving head, and multi-spindle lathes.

Manufactured to a high precision.

Balanced to reduce vibration

Fast Delivery

Further information

Can a liner be extended?

Yes. As material supplies come in standard lengths it has to be cut to suit short magazine barfeeds. Ideally it is cut is equal lengths to achieve the most efficient way of using the material. Lathe spindle lengths vary so to help a liner can be extended to help load the material length required although there is a limit to the extension that can be achieved.

How are they fitted in the lathe spindle?

Kitagawa lathe cylinders have a detector plate fitted and these plates have a series of tapped holes. The liner either has a flange with a matching holes pattern or has a separate flange to house the liner in the lathe spindle