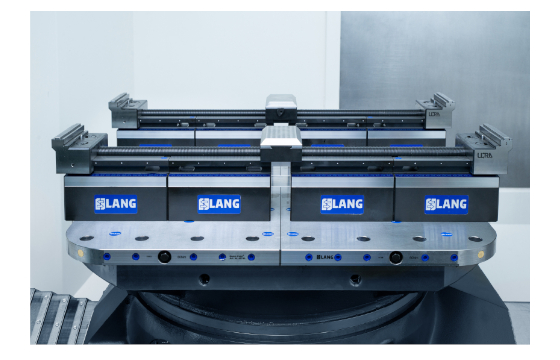

Makro-Grip Ultra

Makro-Grip Ultra allows clamping of large parts

Thanks to the expandability of its modules Makro-Grip Ultra is capable of clamping single or multiple parts of 810 mm length and beyond safely. This capability pushes workholding to new heights and is particularly suitable for mould making and clamping applications of flat and large parts including deformation-sensitive parts.

Different system heights, individually expandable clamping ranges, interchangeable clamping jaw types and a range of useful accessories add to the versatility of the vise.

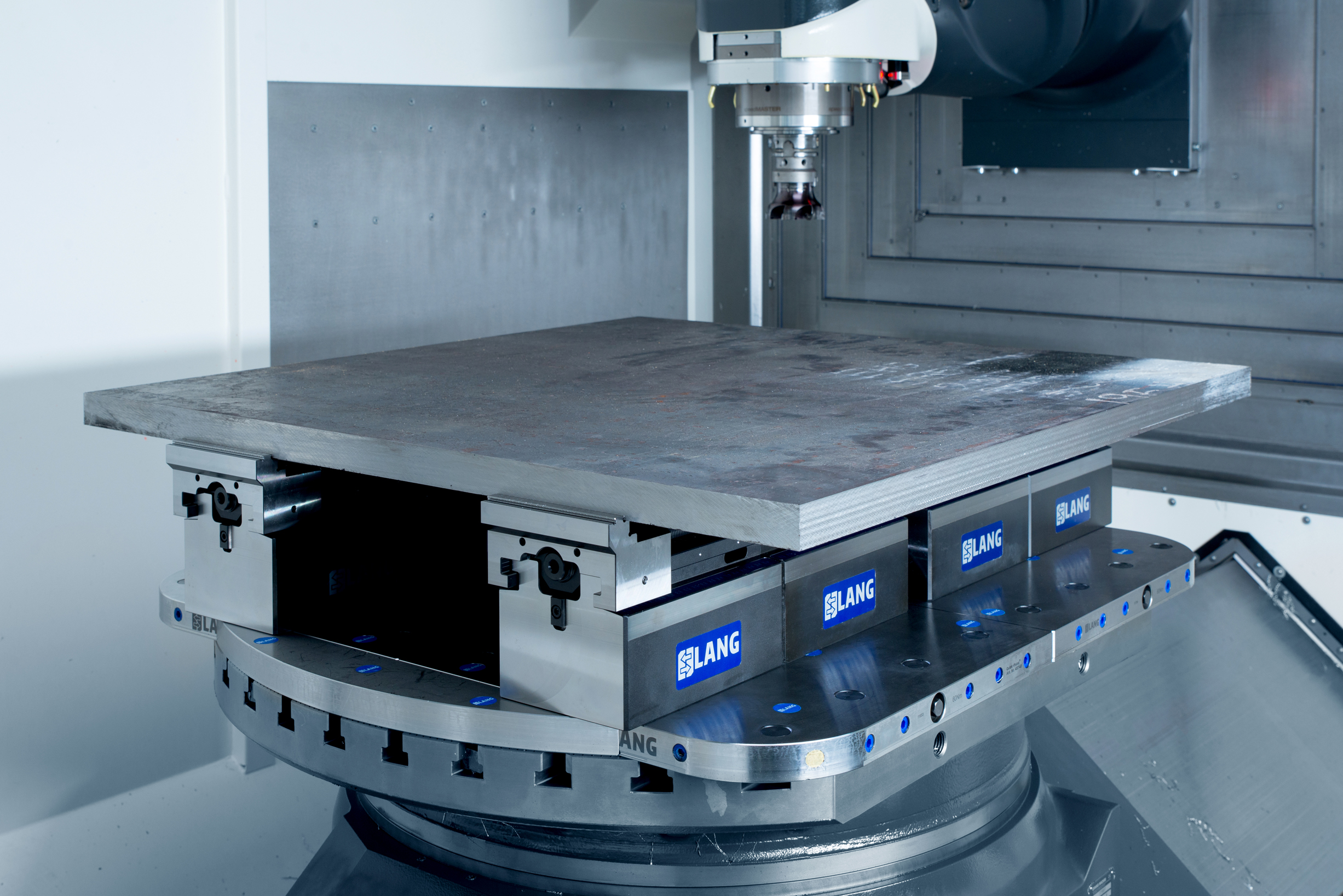

Makro-Grip Ultra is extremely flexible and equally capable of clamping, cubic, round or asymmetrical workpieces. Manufacturers are now able to clamp large, flat workpieces concentrically and combined with the zero-point clamping system allows for changeover within seconds, making it possible to process numerous parts in next to no time.

Centre jaws can be used for clamping multiple parts simultaneously – both with serration or plain clamping steps. A special type of centring plate at the inner ends of the base bodies ensures that the spindle has a clearance of 4 mm to compensate for workpieces that are not identically long.

Each clamping jaw is individually secured by a threaded cap and thus can be moved independently from other clamping jaws allowing asymmetrical and shaped parts to be clamped.

Another key advantage of Makro-Grip Ultra is its ability to machine all five faces of a workpiece without changeover. Depending on the requirements of the workpiece the operator can choose between different approaches and configurations for the first and second operation.

See more at: https://www.lang-technik.de/en/