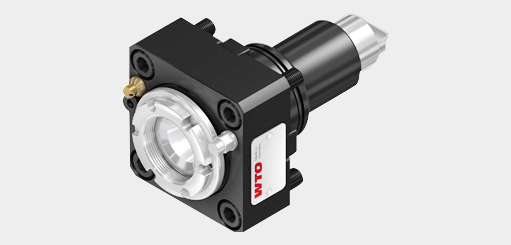

QuickFlex® quick change system reduces tool change time

Dimac Tooling, Australia and New Zealand’s leading supplier of accessories and workholding solutions for CNC milling and CNC turning machine tools, is the agent for the range of WTO high precision static and driven toolholders for turning centres.

For many years WTO has continued to set the benchmark for driven tool technology with its inventions. Their technological and superior products are known for achieving higher productivity and long tool life.

WTO has recently launched QuickFlex® a new and innovative quick change system in one toolholder. Providing an ER collet chuck and quick change system in one toolholder provides a number of benefits including reduced tool change time and higher flexibility.

The comprehensive QuickFlex® system covers a full range of different tool clamping adapter types and sizes and the tool change is designed to be quick, easy and safe with a new one-hand wrench.

Basic elements of the system are the two independent taper connections. The short taper closely behind the thread of the collet chuck is for radial centering and axial support of the QuickFlex® adapter. This taper guarantees the high precision of the system independent of possible abrasion at the cone of the ER collet chuck. The location of the taper behind the thread keeps it protected against chips and dirt which guarantees permanently the high precision of the system.

“WTO’s goal was to develop a compact, simple and safe quick change system for driven toolholders with high cutting performance and long life time key objectives,” said Dimac’s Managing Director Paul Fowler.

“One of the other benefits is that the cutting tools can be pre-set while the machine is operating. That means the set-up time for tool change at the machine can be significantly reduced,” Mr Fowler went on to say.

WTO has also been conscious of the need to offer a product that allows customers to add QuickFlex® when budget allows.

Starting with a minimal investment, the customer can clamp the cutting tools directly in the toolholder using a standard ER collet. Whilst the toolholder can be used without a quick change system initially, quick change adapters can be purchased later.

“WTO offers a quick change starter kit that allows customers to update to the quick change function easily and cost effectively. Step by step the quick change function can be added for reducing tool change time,” Mr Fowler added.

“Like all the products we sell, QuickFlex® is supported by the full back up and support of Dimac technical personnel to ensure the right product is specified for the job and the product operates at optimum performance,” Mr Fowler concluded.

View product: WTO QuickFlex